measuring mash thickness|beer mash temperature chart : companies Therefore, small-scale brewers do not need to adjust mash thickness to influence the final beer. Mashing-In . Mash-in, also called dough-in, is the mixing of the water and milled grist. Mash-in must be performed so that the water and grist are thoroughly mixed together without any clumping. . Measure mash pH - Mash pH should be checked to . WEB5.5M 99% 7min - 720p. The truth about phobias is that they can be overcome with a good fuck with the therapist's big cock in his office. 410.4k 100% 7min - 1080p. .

{plog:ftitle_list}

WEBmafia. heir/heiress. drama. bxg. sassy. Start Reading. like. Blurb. As pessoas entram em nossa vida por acaso, mas não é por acaso que elas permanecem. Quase 20 anos .

The characteristics of your wort are determined by a balance of mash thickness, mash temperature, mash pH, and ion concentration. Using detailed notes and time, you can find the right balance in your brewing system to give you exactly . Deviate from the typical 1.25qt/lb mash and try 1.5qt/lb or even 2.0qt/lb! This author has realized an increase from 70% to 85% efficiency by .

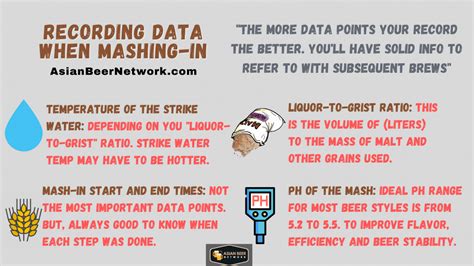

Others will cool the mash to 68 °C (20 °C) before a measurement is taken. So, 15–25 minutes later, we have our pH value. Drats! We discover that our pH is 5.6 and we really wanted pH 5.4. . (2.2 lbs.) of grist (“normal” mash thickness in the 3 liters water per kg malt is assumed) will reduce mash pH by 0.1 pH units. For my non-metric .If the mash thickness is known in qt/lb, multiply by 2.09 to convert to l/kg . Measuring Lauter Efficiency (Batch and Fly Sparging) Table 2 - Table for estimating the brewhouse efficiency loss in the lauter based on the extract . Therefore, small-scale brewers do not need to adjust mash thickness to influence the final beer. Mashing-In . Mash-in, also called dough-in, is the mixing of the water and milled grist. Mash-in must be performed so that the water and grist are thoroughly mixed together without any clumping. . Measure mash pH - Mash pH should be checked to .

A total of 24 friends, family, and BeerMe Brew Club members participated in this xBmt, each one blindly presented with two samples of the thin mash beer and one of the standard mash thickness beer. Given the sample size, 14 tasters would be required to correctly identify the different beer to achieve statistical significance (p<0.05). My question comes with the mash. I know normally, you determine your mash thickness with 1.25-1.5 quarts per pound of grain. If I were to use, say, 1 or 2 qts per pound, what would the difference be in the end product? I'm very interested in forming my own recipes, and I'm wondering if this is a big deal. Thanks!Mash pH is a hot topic among homebrewers these days, but there is a lot to it. Here is a deep dive into pH meters and the nuances of mash pH. . In the section where Noonan discusses the impact of pH on mash chemistry there is nary a hint regarding measurement temperature. Most recommendations to brewers state that mash pH should be 5.2–5.6 .Measurement System. Imperial System (US Standard) Grain Weight. lbs. The total amount of grains used in the mash and boil. Mash Thickness. gal/lb. The ratio of water to grains in your mash. Typically 0.375 to 0.5 gal/lb or ~ 3 to 4 liter/kg. Mash Temperature °F.

This sets the total mash tun volume at 7.85 quarts. With this formula, you can check whether the tun can hold all your grains. How Does Mash Thickness Affect Mash Temperature? Mash thickness affects mash temperature because the thicker the mash is, the higher temperature you need. When your mash is thick, you have less water for every pound . For greater accuracy a pH meter is the appropriate choice for measuring the mash pH. But this greater accuracy comes at greater costs: The cost of the meter; . (old) credit card to set their gaps. A credit card’s thickness is smaller than what I want for my grain mill (i.e., 0.039 inches) but for some people who prefer a finer crush this .

A brewery wanted to know which was the right pH meter and electrode for their process including measuring the pH of mash. Find out our recommendation. 🎃 Use Code: SPOOKY 🎃 15% OFF and FREE Shipping on Orders of 9 or More ⏰ Ends 10/31 - SEE OFFER DETAILS. Food . For the mash thickness experiments the following parameters were kept constant grain type: Weyermann Bohemian Pilsner Malt; grain weight: 70g (for the 2.57l/kg and 5 l/kg series) and 120g (for the second 2.57 l/kg series) . (a measure of how well the mash converted the starches available in the grist). From the few data points that exist so .To figure out a reasonable water/grain ratio ideally, one should do multiple mashes and get experience, but one alternative is to do a brew with about 1.060 OG and note how much water added to get a good mash thickness. Subtract the Mash-tun deadspace, then divide amount of water on amount of grains to get the water/grain ratio.

When checking the mash or wort pH, it’s best to cool the sample to room temperature for an accurate reading. A correction must be made if the sample is too hot or too cold. A pH reading at mash temperature will be off by about +0.2 points. A sample at refrigeration temperature will be off by about -0.01.How to Measure Solder Mask Thickness. While you want your solder mask to be thick enough to protect your circuits, it’s important to measure the solder mask to make sure it’s not too thick. On the side edges and top of the conductor, you’ll want a thickness greater than 7 micron. The maximum thickness for solder masks on finished copper .

Estimated Mash pH = (5.9) + (-2.70 x 0.03) – (5 x 0.025) = 5.7 at 68 °F/20 °C. In the example above, the predicted mash pH is higher than the target. The options for mash pH adjustment are water chemistry, tweaking the grist bill, and adding acid. The equations above show the basics on using water and malt selection to adjust pH.Mash Thickness (qt/lb or liters/kg) Current Mash Temp (deg F or C) Target Mash Temp (deg F or C) Units of Measurement: American Metric. Can I Mash It? Find out if your mash tun is big enough to hold your grain bill plus the strike water. Note! This calculator does not take theI made a mash with Weyermann Pilsner malt and distilled water at a mash thickness that is typical for infusion mashing and then thinned out to ASBC Congress mash specifications. pH was measured using an EcoTest pH 2 meter (ATC type pH meter), and the meter was calibrated using pH 7.0 and pH 4.0 buffers.

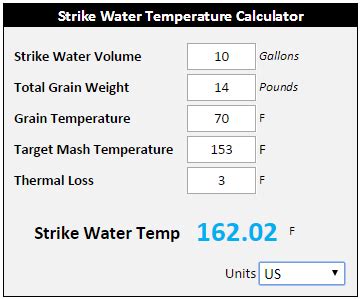

strike temp calculator

Wort lost below the mash-tun spigot, in transfers, in your chiller, in the trub left in the boiler, and even in hoses or pumps represents lost sugars and will lower your overall efficiency. Reduce losses whenever possible for a more efficient brewing system. Mash Thickness Matters. Adjusting the ratio of water to grain, known as mash thickness, can impact mash efficiency. A thinner mash (higher water-to-grain ratio) may enhance sugar extraction but might require longer lautering times. Conversely, a thicker mash (lower water-to-grain ratio) can yield higher efficiency but may require more water.

leeb portable hardness tester

The water to grist ratio is a measure of mash thickness. A thin mash will have a high water to grain ratio while a thick mash will have a lower water to grain ratio, think of soup vs. stew. Studies by Briggs et al (2004) indicate that a thin mash (high water to grain ration) will have higher mash efficiencies across multiple temperature ranges .The Water Amount Calculator at HomeBrewing.com calculates the total amount of water needed for your brew including mash water and sparge water needed. The Water Amount Calculator uses your target final volume, amount of grains, grain retention, mash thickness, equipment loss, evaporation rates and boil time when calculating the water amounts needed.

What criteria determine your starting mash thickness? Most brewers seem to choose something like 1.25 or 1.5 quarts of water per pound of grist, but the choice seems almost arbitrary. My assumption is that thickness of less than 1 qt/lb would just be too thick to work with. I also understand the practical need to start with a thick mash if you . Of course having a mash tun that remains at a constant temperature throughout the duration of the mash and measuring both mash thickness attenuation results at varying temperatures in the say 60C - 75C range by say 0.5C increments would give us a much better overview. #17 koopa, Jan 4, 2015.Measuring Mash pH. Questions about pH and its relationship to brewing are very deep. So deep in fact, that the pH scale was developed and introduced to the world in 1909 by Søren Peter Lauritz . Nice to know that our readers are also watching our video content online. Mash thickness is one of those things that many a brewer takes for granted . Mash Thickness question. Thread starter Triskele; Start date Feb 20, 2024; 1; 2; Next. 1 of 2 Go to page. Go. Next Last. Triskele Member. Established Member. Joined Dec 16, 2023 Messages 36 Reaction score 39 . measure the difference from start to finish and then multiply by 4 if your boil is an hour.

I was watching the latest basic brewing video where they were talking about mash thickness and how a thinner mash (2.0 qts of water per lb of grain as opposed to 1.25) will provide greater efficiency. I'm wondering why this is and if you can make up for it with sparge volume. More. The rest of us need only remember that when we measure the pH of a mash, we want it to be in the 5.2–5.6 range. Given this ideal range and given that dissolved substances can affect that pH, our main goal as brewers is to ensure that the blend of dissolved ions and molecules results in a mash pH that’s in our target range. And the two .

mash thickness range

mash thickness calculator

WEB- Nível 3:Receba 0.00% dos lucros da plataforma. Todo dia pode ser a sua vez de fazer uma grande jogada! Ana Bet - Não fique de fora, aproveite essa oportunidade de lucrar .

measuring mash thickness|beer mash temperature chart